|

The Breadcrumbs widget will appear here on the published site.

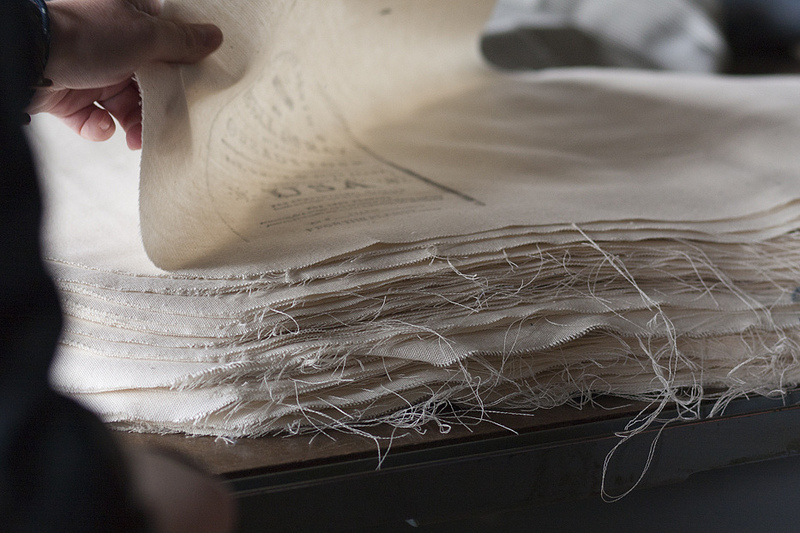

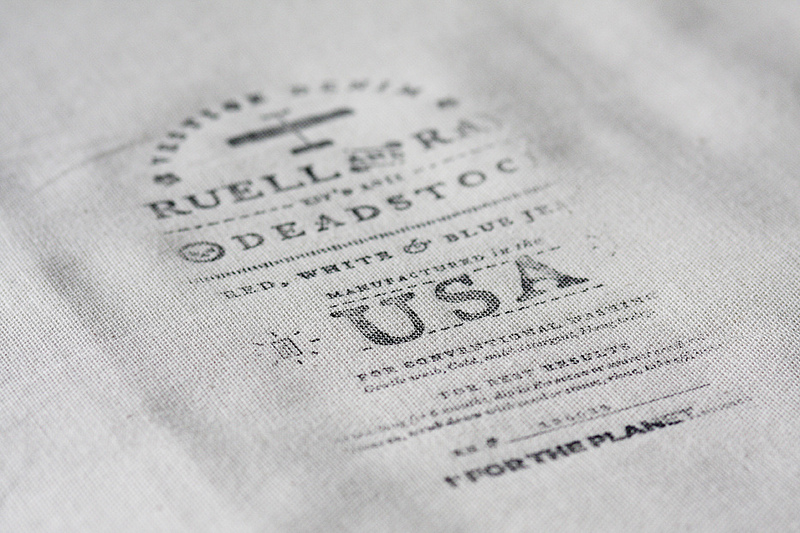

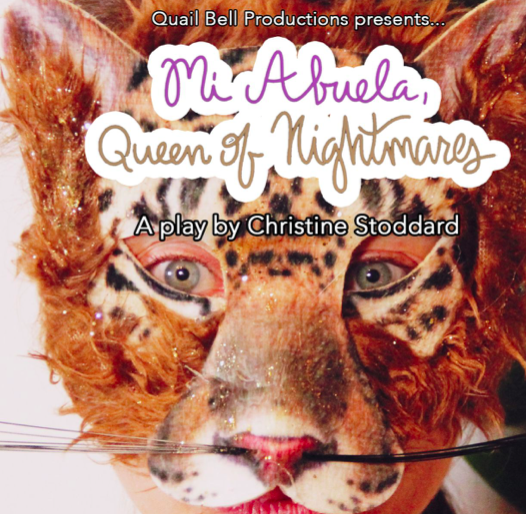

Ruell & Ray/Pointer BrandJeff and I took a road trip to Bristol, Tennessee to visit Ashley James of Ruell and Ray in the historic Pointer Factory, where her brand is made. Join us as we explore how a pair of jeans is made and how a brand is formed. Somewhere between the summer of 1908 and the winter of 1910, there is a man hunting in the woods. He is hunting in those shale filled peaks on the Tennessee-Virginia border. He lines up a shot on his prey and his overalls rip, causing him to miss his shot. He curses the stitch, the tailor, and the general store clerk who sold him the pants. He looks down at his pointer dog, Carolina Bill, and sighs. Bill continues pointing. It hits Landon Clayton King ( L.C. to everyone but his minister) that making a pair of pants can't be nearly as difficult as raising a champion pointer dog. He sets up shop in Bristol with his Pointer Brand, and erects the L.C. King factory. About a hundred years later, that same idea of making a better pair of pants strikes a girl in Georgia. She quits her job and sets out to make it happen. Her name is Ashley James. She sets up shop in that same factory—or at least that's the way I like to imagine it, regardless of the facts. The two stories have a nice a symmetry. We left Richmond before dawn. After five and a half hours of driving and a couple stops for coffee and cigarettes, we pull off State Street and onto 7th. Ashley James is hard to miss. She is leaning against that hundred year old brick, wearing rolled up khaki overalls, a dark wash denim jacket, and a slick billed Nets cap. If you have never been to Bristol, Tennessee, let me assure you that no one dresses like that there. We park across from the factory. It's two stories of tan brick, large paneled windows that can be propped open, and the raised letters of L.C. King on the entrance to an office that looks like it was last updated in the 1960's. We spend a few minutes talking with Ashley outside before we head inside. It is exactly as I imagined it would be. The walls are covered in wood paneling and the desks piled with papers. Ashley talks with the two receptionists as Jeff and I examine the walls. We look through framed posters of the brand logo, a framed pair of children's overalls that has been worn by every generation of the Kings, and a certified document showing the lineage of Carolina Bill and his pedigree. The receptionists welcome us in an accent that says they were born and raised in the Tennessee woods. They speak to us with big smiles and are uncommonly sweet. They ask Ashley how the overalls are working. She turns her foot to show her pants and says they are fine. We walk through the door into the first level of the warehouse. Ashley points out what different machines are used for. There isn'y much light beyond a few flickering fluorescents and the light coming from the second level. I am reminded of being much younger and playing in the empty offices and cubicles in the downsized administrative power plant building where my father worked. We follow Ashley upstairs to the "floor." There are various types of sewing machines. Some are as old as the factory and some look brand new. There are wires that look like veins from the machines to the ceiling and to the rows of lights above our heads. The machines outnumber the people by probably four to one. It makes it seem like most people are on vacation, or that we are visiting during off-hours. We follow Ashley to the main room. People wave and nod and everyone seems to ask how those overalls are working. She has that same gracious response. We stop and talk with one woman sewing aprons. Mary has worked here for thirty years and is instrumental in helping Ashley manufacture Ruell and Ray. Ashley takes us to a small table that is Ruell and Ray. The table holds a small stack of jeans, masonry jars full of rivets and buttons, and a hand press. We ask her to show us the riveting process. She takes a pair of jeans and marks the rivet points with a yellow pencil, fixes the type of rivet into the press, lines up the points, and pulls herself off her stool to press. Then she does the buttons. I try to imagine her having a large order to fill and working the hand press. Hours of work for each set of rivets and buttons. It seems far too daunting a task for one person. My respect for Ashley grows with each rivet. We head to the next room to look at her fabric. She takes us to a cart and pulls up the rolls as she explains what each one is. There is a green that she uses for the pocketing and lining around the button fly, two light tans, and a bolt of Kuroki deadstock. The Kuroki, made from sugar cane, was originally in production in 2006. I wish I knew more about how denim was made to have what I feel would be a better understanding of what the difference in these fabrics is. These are for an upcoming order she has for Park and Bond. She takes us to one of the large cutting tables and shows us her hand stamp. Like any stamp, she rolls it in ink. It is about the size of an iron and convex on the front. She rolls it over the denim and leans in to look at the result. She says how she likes where the edges are not quite as visible, where there wasn't enough ink on the stamp. I like it myself. It has a feeling I can't quite place, but it is pleasing to the eye. She walks us down the table so we can see her jeans getting cut. The cutter rolls out her pattern across the table. I am stuck on the chainmail glove on his left hand for a moment. I quickly realize it is a practical piece of safety gear and that he is not into steam punk fashion. He side eyes me as I smile awkwardly. I have never seen a pattern in real life before. The cutter takes me through the pattern and how it's supposed to be cut. Each cut is done in sections: right front leg, back left pocket, left front leg, etc. He takes the pattern and cuts a stack of, say, 100 pieces of denim. So you have the stacks of each piece of the jean and you take them to stitching. Stitching sews them together and send them to Ashley for the rivets and buttons, then the hand stamps. After that you package them and send them down to shipping. Shipping takes them where they need to go. Pretty simple overall but each step is as tedious as the next or the one before. It seems like an agonizing amount of repetition. Ashley and I take a seat on a chipped bench to talk about her brand and her vision. After I have taken a few pages of notes, we decide it is time to get something to eat. We say our goodbyes to the Pointer factory and its employees and join Ashley and her significant other for lunch at The State Line bar. We swap stories and make future plans, laughing with the server at the country phrases he uses. Ashley and her S.O. are on their way to Georgia and we have to head back to Richmond. We leave Bristol with a better sense of Ashley James and what goes into a pair of pants. We first met Ashley James at Need Supply Co.'s “Meet the Maker” event. She was there with her friend and fellow designer Billy Moore of Cause and Effect. We were blown away by her jeans at what we later learned was one of her first showings. Ruell and Ray is a fledgling brand with all designs made in the U.S. Everything is as locally sourced and handmade as possible. Ashley uses as much deadstock as she can, and 1% of the brand's proceeds go to helping the environment.

CommentsComments are closed.

|

|