|

The Breadcrumbs widget will appear here on the published site.

Making Magic in the LabBy Doe Deere QuailBellMagazine.com When I embarked on my lipstick-making journey, there was one question I was asked over and over by everyone I met. It was usually said with a note of surprise or disbelief in voice: “So, how exactly do you make lipstick?” It’s something I’ve often wondered myself. Specifically, how a girl like me who nearly failed chemistry in school, ended up in an industry that involves labs, chemists and long-tailed formulas. It’s no secret that I am no scientist – I couldn’t tell you the atom weight of cobalt or the melting point of titanium. But what I do know is that I live & breathe color, and have been using cosmetics long enough to know what works and doesn’t work for me. So that’s the approach I decided to take with my line: as a consumer. In other words, make something that I would use! There are 3 key elements to making lipstick: Formula Color Packaging Formulation In a nutshell, lipstick is a mix of oils, pigments and waxes–together, they form a mass that is hot-poured into forms and cooled down to create lipstick. There are thousands of formulas out there–some allow for more moisture, more staying power, sheer or opaque finish. I felt that there was plenty of glossy lipstick out there but a huge deficit of a good low-sheen lipstick with high color payoff. So that’s what I wanted to make. Creating a good formula can take up a lot of time and resources. I ended up finding a laboratory that helped me develop a creamy, non-drying lipstic that can hold lots of pigment! If you have any experience with lipstick at all, you know that it’s almost impossible to tell pigmentation by simply looking at it in the tube. A strongly-pigmented red will look the same as a sheer red. Come to think of it, I’ve bought lipsticks in the past thinking they will be bright but they always went on disappointingly sheer. The Opacity factor ended up being something I had to FIGHT for, tooth and nail. Having made millions of mediocre lipsticks, the lab didn’t quite understand why I wanted mine to be so pigmented. I devised a so-called One-Stroke Opacity Test to test lipstick’s pigmentation level: only those with full coverage were approved and made it into production. Color development “The best chemists are color-blind,” once said a colleague of mine who’s been in the business for 30 years. Indeed, in an industry that is supposed to be all about color, I felt strangely alone in my dedication to develop shades that were a little (or a lot!) outside the traditional spectrum. The typical color-developing process is quite uninspiring:

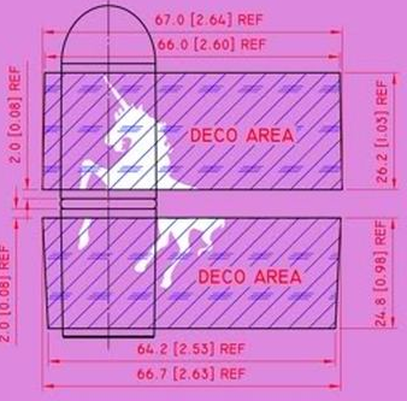

That’s it. There are two things inherently wrong with this process. 1) Everyone’s making copies of each other’s stuff, and 2) Nothing new is being invented, ever. Is it any wonder we have stores full of cosmetics that look exactly the same?! I immediately knew that this approach would not work for Lime Crime. Being fanatical about color, I decided to learn how to create custom lipstick shades from scratch. Gaining access to a color lab (I felt like a kid in a candy store!) gave me an opportunity to experiment and concoct some of the most outrageous shades and combinations! It was more than a learning process; it was like having all my questions, that have been fermenting in my head for a long time, answered at once: Is it possible to make neon lipstick? How about blue? Is it legal? Why isn’t anybody doing it? You can imagine how crazy people thought I was for even asking these questions. In an industry that’s more about trends than creativity, coloring outside the lines is, well, …a crime. Imagine having to convince seasoned chemists that you indeed want purple that purple and pink that pink. In the end, I’m very glad I went with my gut and developed a range that helped set Lime Crime apart from other brands. As for those who doubted No She Didn’t in the beginning? They ended up rooting for it the most in the end! Packaging I’m a girl, so I like my personal things to look cute. A quick walk through Sephora revealed that most brands treat their packaging almost as an after-thought–I’ve seen lipsticks containers that were boring, ugly and even–oh no!– exactly the same with different logos printed on!! This is something I couldn’t agree with – after all, I see makeup as an accessory and cuteness is non-negotiable. We soon found out why nobody bothers with it–creating a custom container is an extremely slow, arduous and expensive process that can take 3-6 months. But since I couldn’t see myself carrying a plain black case, we decided to take the chance. I envisioned a bright pink tube adorned with a sparkling unicorn and just enough whimsy to make people remember the brand. This was my first packaging design project, so naturally I hit a lot of bumps on the road, but the hardest part was to convince the factory to print a solid unicorn onto 2 parts of the lipstick container (base and cover). One look at the diagram above and you’ll know something is off: the unicorn looks disjointed, like someone cut off its front hoof and most of its butt. The reason you don’t ever see a this type of design is because printing all the way to the edge is not considered a ‘safe printing area.' I’m very glad we pushed the factory to give it a try–and what do you know, it came out beautifully! Most importantly, it looks like something from my world and something I’d be proud to have on me at all times. So there you have it–my lipstick story, hiccups and all!

Comments9/25/2012 10:47:32 pm

Great piece of writing, I really liked the way you highlighted some really important and significant points. Thanks so much, I appreciate your work. Comments are closed.

|

|