|

The Breadcrumbs widget will appear here on the published site.

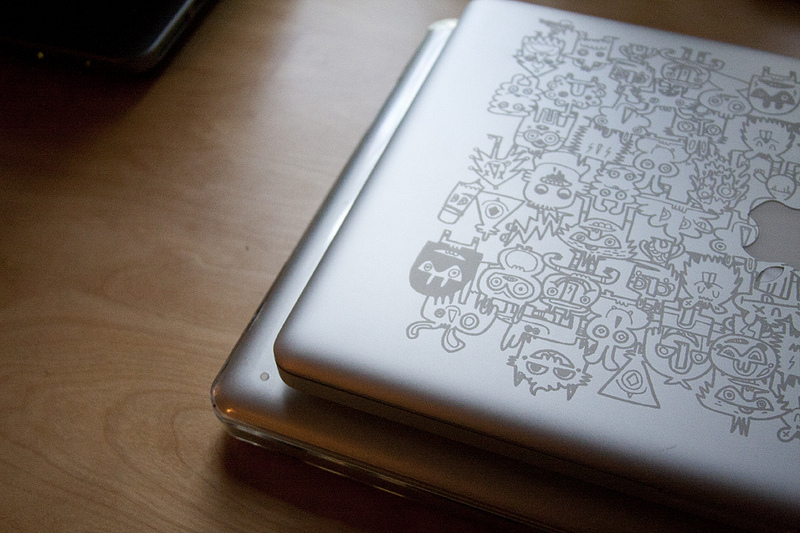

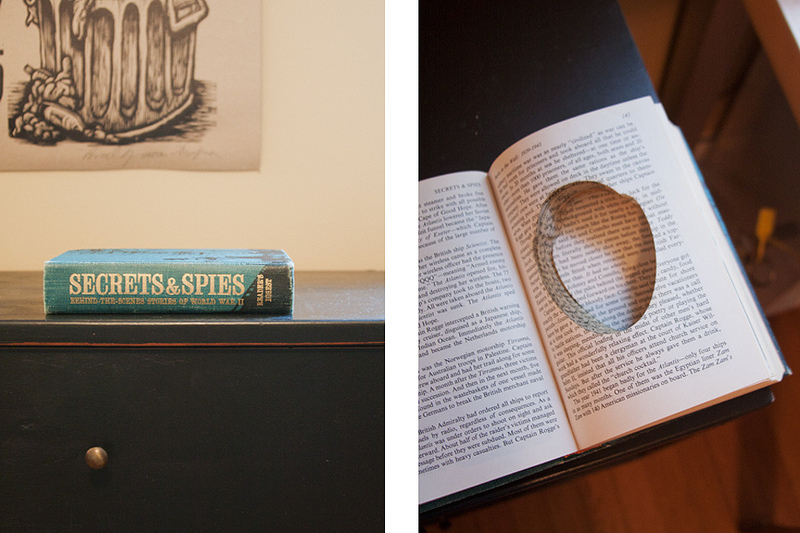

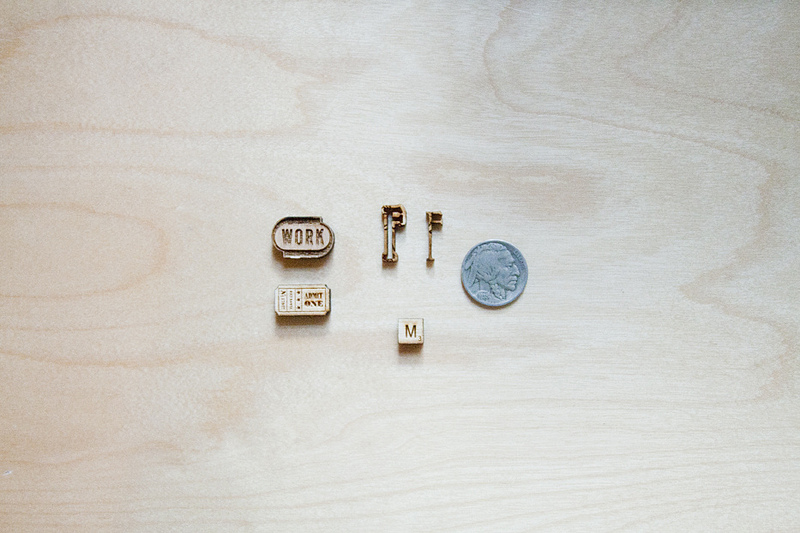

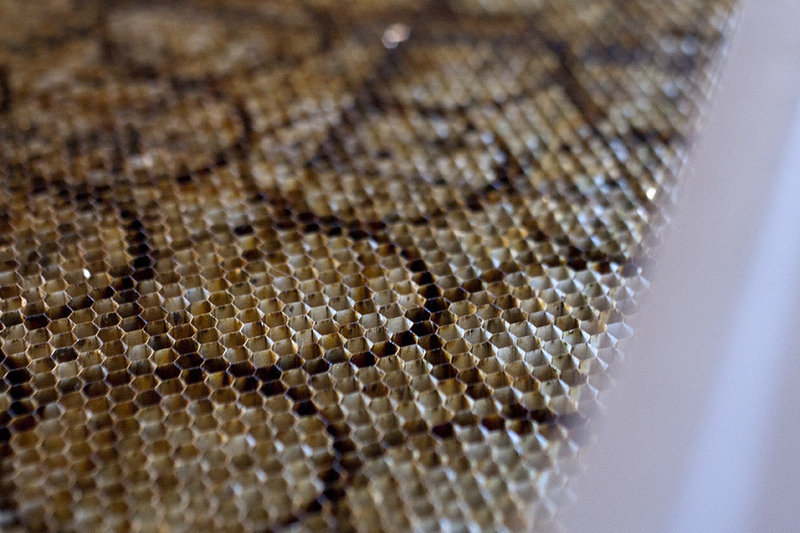

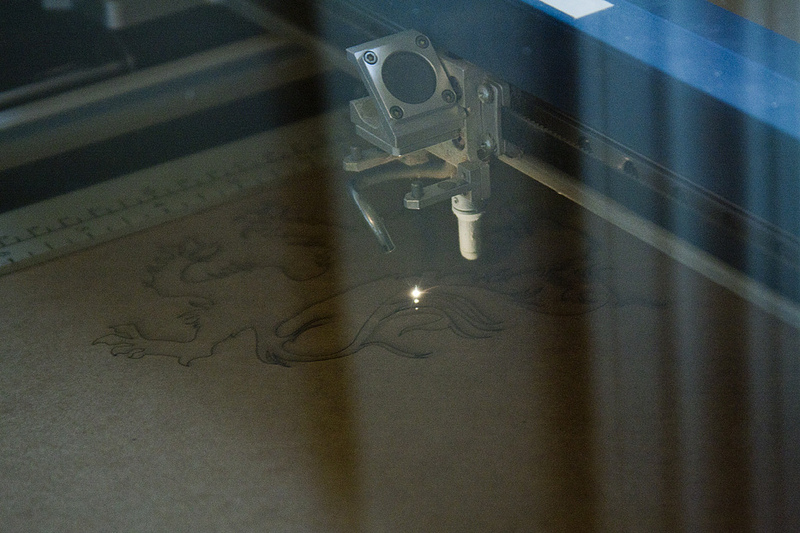

A Variety of ApplicationsJeff and I get an inside look at how laser engraving works with Jason Lefton and BIG SECRET. Join us for an enlightening experience and a few choice cuts. We park on the Boulevard in Richmond, Virginia and walk to the address we were given. Jeff and I hesitate at the door. The only sign is for some therapist upstairs. We head up anyway. I am relieved not to see friends and family sitting around for some intervention. Jason Lefton gets up from his desk and welcomes us into the office of BIG SECRET. He thanks us for coming and Jeff and I spend a few minutes discussing how excited we are after seeing some of the things he has produced. Jason takes me to the bookshelf behind his desk to show me the wide range of what he can do. He starts with a number of business cards, and wedding invitations he has done. Some have just been burned with the laser. Other cards have the designs cut through. I turn the card stock in my hands inspect the cuts. The lines and the curves and the angles are so precise I can’t imagine it being cut by hand. Jason picks everything up so gently and hands it to me to touch and hold as he talks. I try to handle everything as carefully as he explains what I am holding and how he did it and who or what it was for. He shows me how etching and marking looks on different materials. He shows me sunglasses and plastics. He pulls down a few glass jars that he etched for Grow Interactive. The precision is the same but I am starting to pick up on the different effect the laser has on different materials. He explains the differences in power levels and speeds. Depending on the power and the speed the laser will cause different depths and colors. The variations in color are easiest to notice in wood. Jason continues to pull things off the shelf that I don’t realize are pieces and projects they have done. He pulls down a book and opens it. The center is cut out and a wedding invitation is in the hollow space. He pulls a bag of tiny wooden pieces that are exact even in miniature. They can’t be any bigger than a nickel. I feel a bit ashamed of myself because I can only continue to say “wow.” I feel like I should have a better exclamation or be able to articulate my thoughts. Unfortunately, no words beyond “wow” are available in my brain. He sets the last pieces back and suddenly smiles. He pulls out his new “business card.” It is a tiny wooden circle with the BIG SECRET logo. I share in his delight. If this was my business card everyone would be receiving it. The engraver is about the size of a copy machine. It is blue and grey and it looks like it should be in an office building somewhere. Jason opens the top and takes us through each part of the machine. The cutting table is a series of holes that keeps your object from moving and with the help of the exhaust system keeps it cool. There are burn marks and everything has a golden tinge to it. It looks like a giant honeycomb to me. Jason takes a few minutes demonstrating the laser and how he can set a center point and a home point. The laser always goes back even when you turn off the machine. He walks over to a laptop and pulls up the program he needs. The program saves all the images and projects he has already worked on. He clicks on one and explains the controls. He sends a picture of a lion to the engraver. Jason looks at us and asks if we are ready. We both nod. He clicks on the exhaust and walks to the control panel. He hits a button and the show begins. The laser comes to life and moves to the center point. The sounds that accompany the laser seem to fit. As the laser moves and starts to cut it sounds like Robocop walking or like you are taking fire from Stormtroopers in Star Wars. I am expecting to see a beam of red light. It is more just quick flashes of bright, white light. Jason explains how it is working as it continues cutting the piece of cardboard he set inside. The charge fires into a series of mirrors thus concentrating and directing the beam. The final mirror is at a 45 degree angle and reflects it into a 2” lens. The lens focuses your laser as it cuts. The compressor kicks in again and the heat goes through the blower and out the window. The movements of the laser are so minute that I can only tell by looking at the cardboard that it has moved at all. I can see the outline of the lion. Just as fast at it started, it is over. The laser falls back and everything is calm again. Jason opens the top and picks up the cardboard. He pops the shape out and shows me how you always have a negative with that cut. You have the shape and the outline. Jeff and I exchange smiles. Jason hands me the lion. We all share a moment of accepting and understanding how awesome the machine is. Jeff is packing his cameras and I am trying to catch up on notes. Jason tells me about the new shop and the move he is planning. It is in the newly dubbed Arts District. Right there in Jackson Ward where we all enjoy First Fridays. He has a new machine that can double his output and the space sounds perfect. He says it is time to change and the company has grown. I can’t think of a spot more perfect for BIG SECRET. Jason Lefton started BIG SECRET as an experiment and a hobby. The company has grown due to hard work, an open mind for trying something new, a refusal to be pigeon holed, and an effort to inspire creative collaborations. I was awed with everything I saw. I look forward to all the new things that will come out of a very innovative company. I am already thinking of a dozen ideas that would be perfect to collaborate on. Jason had a description for the laser engraver, but I can’t help but think its the perfect phrase for BIG SECRET itself. It is truly a company with “a variety of applications.”

CommentsComments are closed.

|

|